Outdoor unit

Ecodan Multisplit

- Compressor

The PXZ series units by Mitsubishi Electric use dual rotary compressors, operating with R32 refrigerant. They ensure smooth system operation, excellent heating capacity and durability, even in tough environmental conditions. The compressors are made using inverter technology with a modulated operating frequency of 15-130 Hz.

Rotary compressor

To achieve smaller size and higher efficiency, Mitsubishi Electric rotary compressors use the original “Poki Poki” motor and “Heat Caulking” thermal insulation. They are designed to meet the requirements of residential and commercial sectors. Additionally, the development of the innovative 'Split Center Plate' production method has further reduced size/weight and increased performance (energy efficiency).

Automated production line control and individualized production techniques lead to a very low defect rate and high product reliability. The quality control process, involving robots and experienced personnel, ensures that each compressor is tested before reaching the customer. This is why Mitsubishi Electric's quality is known worldwide.

Inverter technology

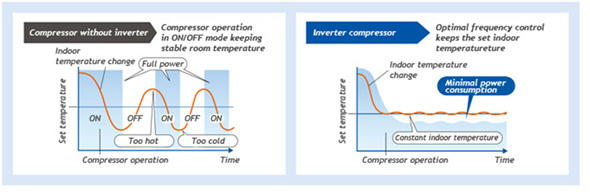

The inverters electronically control the voltage, current and frequency of electrical devises such as compressor motors in heat pump. They receive information from sensors that monitor operating conditions and regulate the speed of the compressors, which directly regulates the power of heat pump. Optimum frequency control reduces excessive electricity consumption and ensures the most comfortable room environment.

Mitsubishi Electric inverters ensure maximum performance and optimum frequency control. The result is optimum power supply for all heating/cooling ranges which leads to maximum comfort (with minimum energy consumption). Quick performance, comfort and low operating costs are the commitments of Mitsubishi Electric.

Economical operation

Low operating costs are a key advantage of inverter devices. Combined advanced inverter technologies with state-of-the-art electronic and mechanical technologies, create synergies that improve heating efficiency. The result is better performance and lower power consumption.

Compressors without frequency converter are started and shut down several times to maintain the set temperature. This repetitive on/off operation consumes excessive amounts of electrical power and affects the service life of unit. Compressors equipped with a frequency converter run continuously – the frequency converter quickly optimizes the operating frequency according to temperature variations. This ensures energy-efficient operation and a more comfortable indoor temperature.

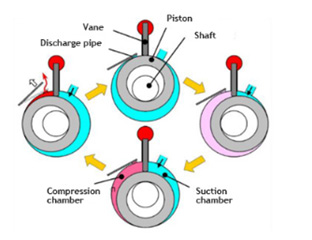

Structure and operating principle

The compressors works by rotating two pistons located on the common shaft. The refrigerant sucked into the compressor is compressed by the rotating piston. The hot, high-pressure gas leaves the compressor and is directed to the heat exchanger. The suction and compression process can be carried out simultaneously in the suction chamber and the compression chamber, which are separated from each other by a vane.

PAM (Pulse amplitude modulation)

PAM is a method of controlling the current, by adapting its path to the voltage. This allows energy to be used more efficiency, with fewer losses. The PAM control allows 98% efficient use of the energy consumed.

PAM regulates the shape of the current waveform by bringing it closer to the voltage waveform. Extremes are reduced and 98% of the energy is used.

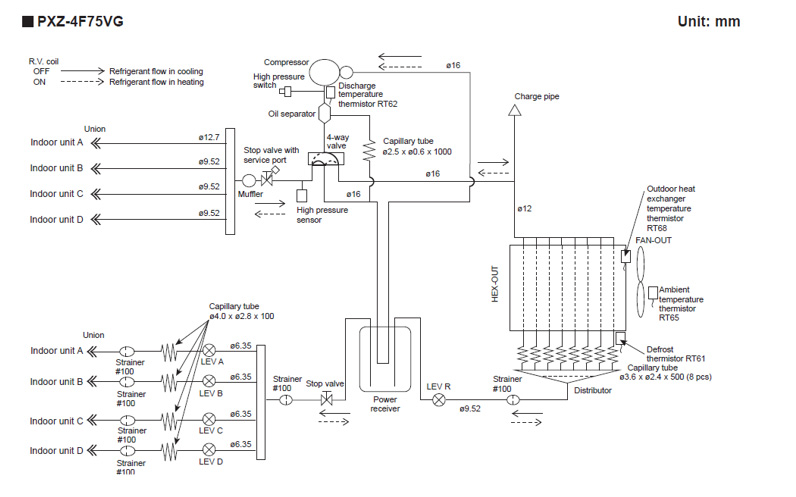

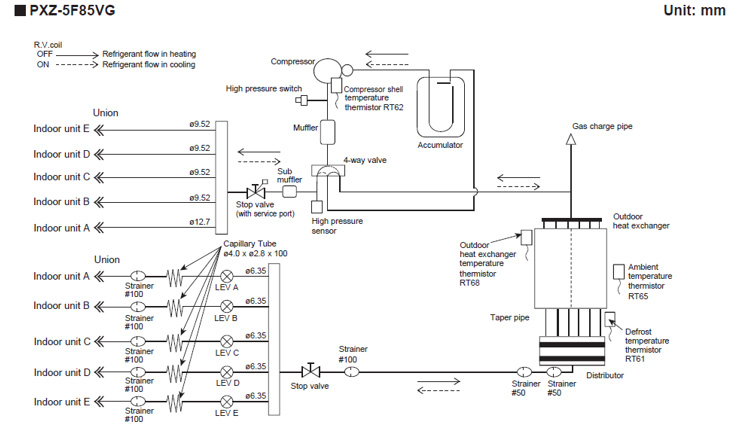

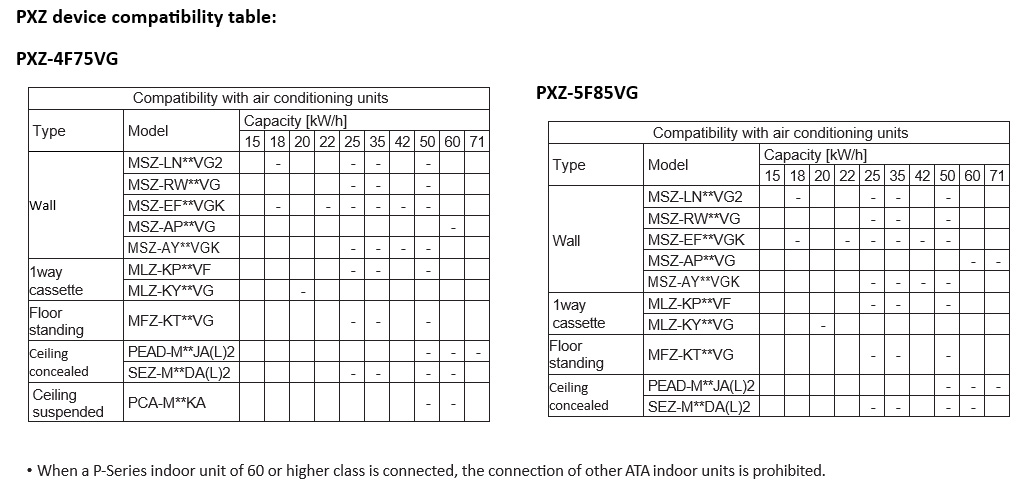

- Refrigeration system

The refrigeration system of the PXZ unit differs significantly from the units/type presented in this section. It has been equipped with separate refrigeration connections along with an individual expansion valve for each unit. These allow the unit to operate in several alternative operating modes. The outdoor unit can be combined with the Ecodan hydronic module and air conditioning indoor units. The Ecodan Multi Split system makes it possible to operate in heating mode with air-conditioning/central heating units, cooling mode with air-conditioning units or provide hot water preparation. The unit is an excellent solution and works perfectly at any time of the year. In summer, it allows cooling multiple rooms through several air conditioning units and providing hot water. In winter, on the other hand, it makes it possible to heat through air-conditioning units or a central heating system and produce domestic hot water.

LEV electronic expansion valve

LEV electronic expansion valve

Expansion valves play an important role in the refrigerant circuit – they determine the ability to adjust the flow rate of refrigerant in the entire system and affect the comfort of the internal environment. Therefore, it is very important to adjust the pressure relief valves precisely. The opening/closing process of the LEV expansion valve is controlled by pulsing signals. Mitsubishi Electric uses electronic expansion valves that can be adjusted up to 500 pulses for optimum operation.

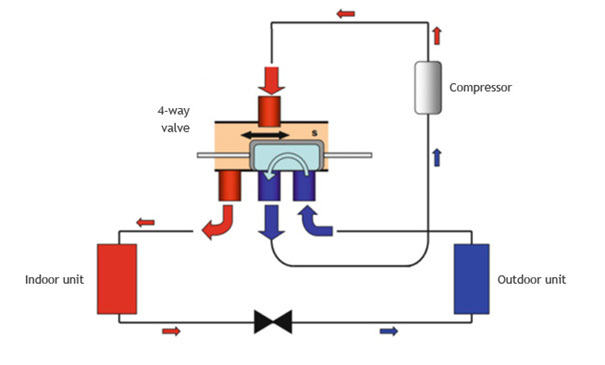

Four-way valve

The four-way reverse valve is used to change the direction of refrigerant flow in the refrigeration system. The valve is used to switch heating/cooling modes and reverse the refrigerant flow during the defrosting process of the unit. During this process, the unit reverses the refrigerant flow and extracting heat from the water in the central heating circuit, melts the frost accumulated on the exchanger.

Heating operation

Cooling operation/Defrost

- Fan

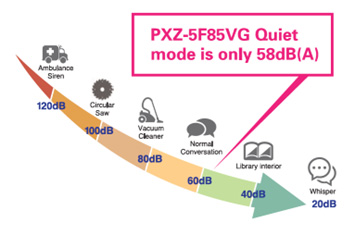

The heat pumps of the PXZ series are equipped with fans driven by a DC motor. It guarantees significantly higher efficiency than the corresponding AC motor. The shape of the blades has been optimized in the units, thus reducing the volume of air flow. Combined with the appropriate shape of the diffuser, the noise of the outdoor unit has been reduced.

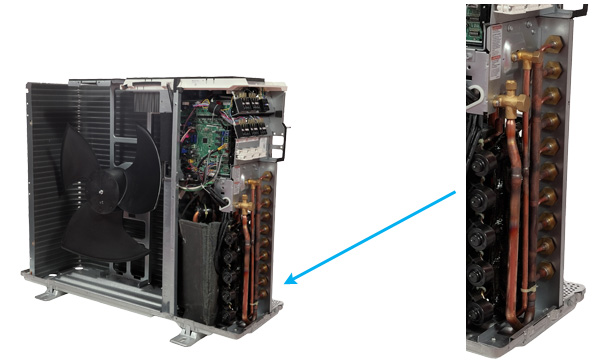

- Heat exchanger

The heat exchanger of the Ecodan MultiSplit PXZ unit is constructed of two copper pipes with aluminum fins.

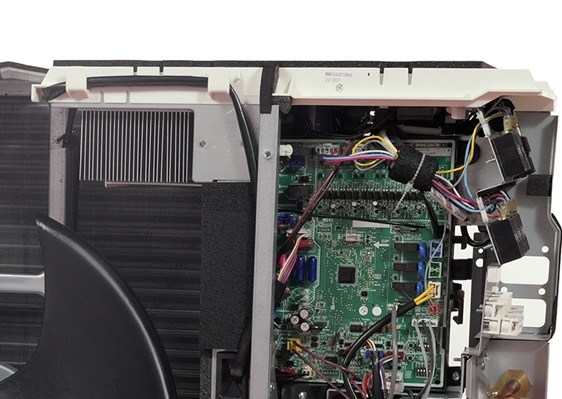

The heat exchanger of the Ecodan MultiSplit PXZ unit is constructed of two copper pipes with aluminum fins. - Inverter board

Control board integrated into the outdoor unit of heat pump. It is cooled by a radiator, using outside cold air. In general, the main function of the inverter board is to control the heat pump. However, it has some additional interesting functions worth mentioning. Below you can find a description of several of them:

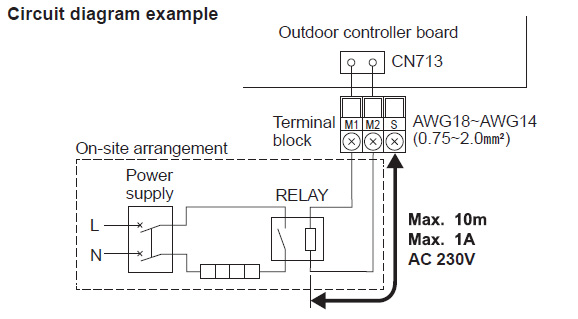

Drain hose heater connector – MAC-062RA-E

An optional heater of drain pan or heating cable can be connected to the outdoor unit. This set can be used to activate the electric heater to avoid freezing of condensation after the defrost process. The defrost signal is active for 15 min after the defrost process starts.

Radiator – electronics cooling

The electronics of the system are cooled by external air. Airflow is generated by the underpressure caused by the fan.

- Temperature sensor

The outdoor air temperature sensor is a resistance sensor integrated into the outdoor unit. It is placed in a plastic housing to minimize the effect of radiation on the sensor reading.