Outdoor unit

PUZ-WZ R290

- R290 indoor leakage protection kit

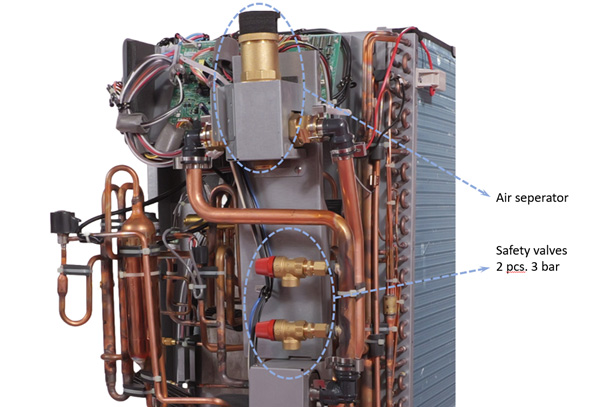

The solution is designed to minimize the potential risk of leakage and leakage of R290 refrigerant into the building along with water. It consists of two safety valves (3 bar) and one air separator. Their operation causes the refrigerant to be released outside the building, eliminating the possibility of a potentially explosive environment.

- Heat exchanger

The heat exchanger is coated with an anti-corrosion coating which is particularly effective in areas with high levels of air pollution. Harmful substances in the air can damage the aluminum radiator fins, reducing the efficiency and lifetime of the appliance.

The heat exchanger is coated with an anti-corrosion coating which is particularly effective in areas with high levels of air pollution. Harmful substances in the air can damage the aluminum radiator fins, reducing the efficiency and lifetime of the appliance.

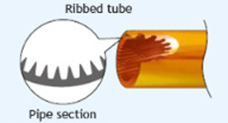

The heat exchangers use improved, corrugated tubes to increase the heat exchange surface. More heat exchange surface means more efficiency.Structure of heat exchanger

- Fan

The R290 PUZ-WZ heat pump units are equipped with a fan driven by a DC motor. By adjusting the position (distance from the heat exchanger and bezel), increasing fan diameter and optimizing blade shape, the air flow noise is reduced. Combining it with the right shape of the diffuser, outdoor unit operation noise is reduced.

- Refrigeration system

The PUZ-WZ50/60/80VAA units use R290 (propane) as the refrigerant. It is a colorless and odorless organic compound. As a saturated hydrocarbon, it is characterized by high energy and short combustion time. Although it can be explosive at certain concentrations, its use as a refrigerant in Mitsubishi Electric heat pumps is carefully designed for maximum user safety.

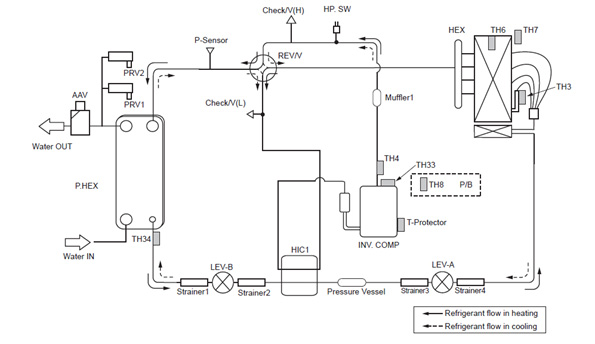

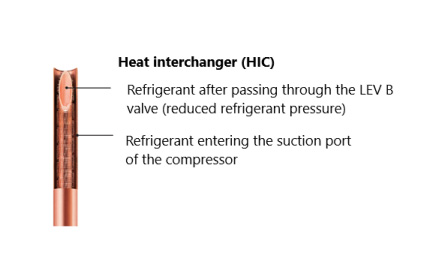

Heat interchanger HIC

Objective: Partial or complete evaporation of the refrigerant.

The result: Reducing the electricity demand of the compressor which results in increased energy efficiency of the refrigeration system. It also allows the water system to operate at a higher flow temperature.

In PUZ-WZ units, a heat exchanger (HIC) from the Zubadan series units has been implemented. One of the tasks of the heat exchanger is to optimize the discharge temperature, which is a significant aspect for devices using the R290 refrigerant due to the properties of propane. The high-temperature refrigerant from the plate heat exchanger and the low-temperature refrigerant from the evaporator can exchange heat before reaching the compressor, significantly reducing the compressor load, and facilitating the increase in discharge temperature.

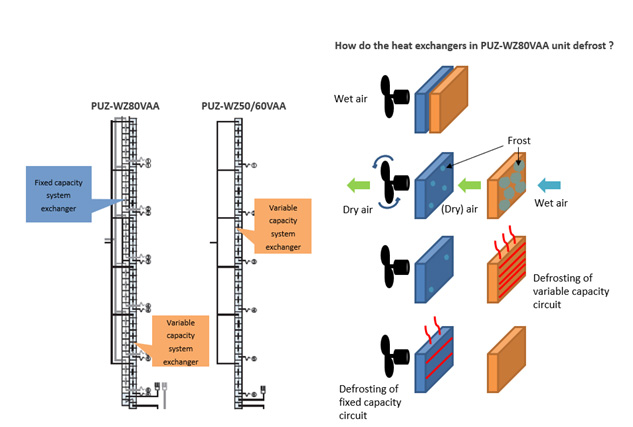

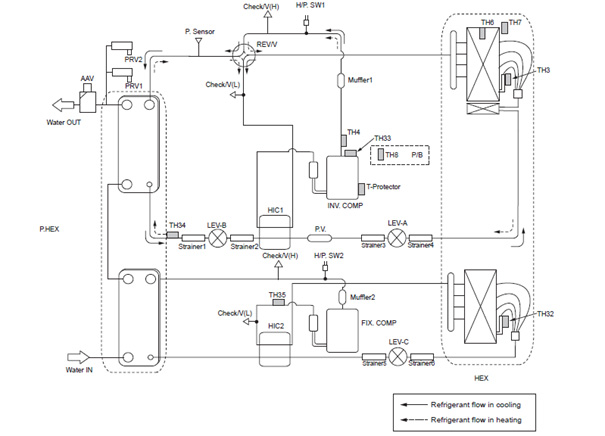

PUZ-WZ80VAA

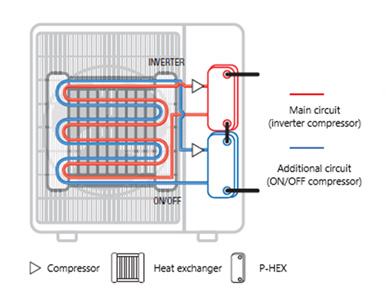

The PUZ-WZ80VAA unit is equipped with two independent cooling systems. The main system features an inverter compressor, which, by allowing for variable speed, enables adjusting the performance to current needs. When the demand for heating power is low, only this system operates. With a decrease in the ambient temperature and an increase in the demand for heating power, the additional system is activated. It is equipped with a compressor of constant capacity, which means it operates at full capacity when turned on. Water in the central heating circuit first flows through the system with constant efficiency and then is heated to the appropriate supply temperature by the variable efficiency system.

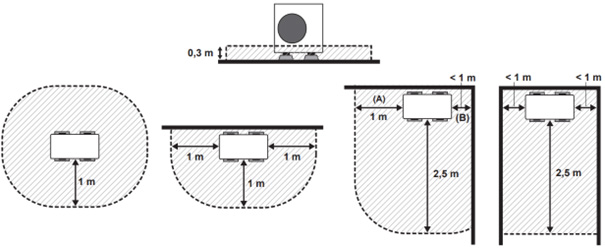

Protective zone

The protection zone is defined as an area near the product within which the following elements are not allowed: building openings, basement entrances, drains or sewer connections. The protective zone must not include neighboring buildings or areas of public traffic, such as lot boundaries or neighboring properties, sidewalks or driveways. In case of leakage of refrigerant, everyone must be protected from exposure to danger and from refrigerant entering the building.

No sources of ignition are allowed in the protection zone, e.g:- open flames

- electrical installations

- grills

- lamps

- electrical sockets

- doorbells

- lawnmower cables

- safety switches (disconnectors)

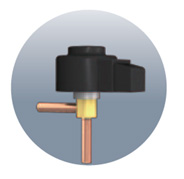

LEV electronic expansion valve Expansion valves play an important role in the refrigerant circuit – they determine the ability to adjust the flow rate of refrigerant in the entire system and affect the comfort of the internal environment. Therefore, it is very important to adjust the pressure relief valves precisely. The opening/closing process of the LEV expansion valve is controlled by pulsing signals. Mitsubishi Electric uses electronic expansion valves that can be adjusted up to 500 pulses for optimum operation.

Expansion valves play an important role in the refrigerant circuit – they determine the ability to adjust the flow rate of refrigerant in the entire system and affect the comfort of the internal environment. Therefore, it is very important to adjust the pressure relief valves precisely. The opening/closing process of the LEV expansion valve is controlled by pulsing signals. Mitsubishi Electric uses electronic expansion valves that can be adjusted up to 500 pulses for optimum operation.

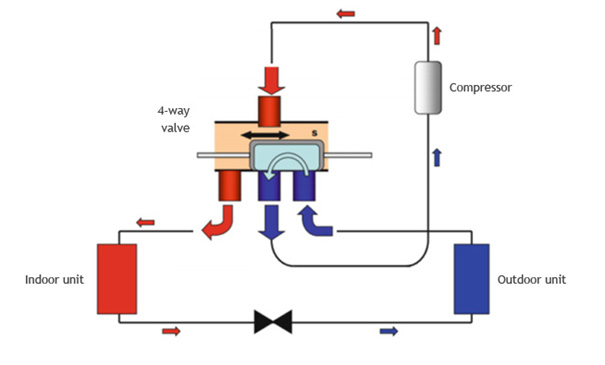

Four-way reverse valve

The four-way reverse valve is used to change the direction of refrigerant flow in the refrigeration system. The valve is used to switch heating/cooling modes and reverse the refrigerant flow during the defrosting process of the unit. During this process, the unit reverses the refrigerant flow and extracting heat from the water in the central heating circuit, melts the frost accumulated on the exchanger.

Heating operation

Cooling operation/Defrost

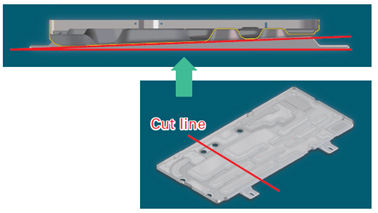

- Drain pan

R290 PUZ-WZ units use the drain pan of the single-fan housing design known from Zubadan heat pumps. The special shape of the base of the drain pan and its slope significantly speeds up and optimizes the condensate drainage process. Better condensation drainage also reduces a risk of freezing.

- Compressor

The PUZ-WZ series units by Mitsubishi Electric use dual rotary compressors, operating with R290 refrigerant. They ensure smooth system operation, excellent heating capacity and durability, even in tough environmental conditions.

Rotary compressor

To achieve smaller size and higher efficiency, Mitsubishi Electric rotary compressors use the original “Poki Poki” motor and “Heat Caulking” thermal insulation. They are designed to meet the requirements of residential and commercial sectors. Additionally, the development of the innovative 'Split Center Plate' production method has further reduced size/weight and increased performance (energy efficiency).

Automated production line control and individualized production techniques lead to a very low defect rate and high product reliability. The quality control process, involving robots and experienced personnel, ensures that each compressor is tested before reaching the customer. This is why Mitsubishi Electric's quality is known worldwide.

Inverter technology

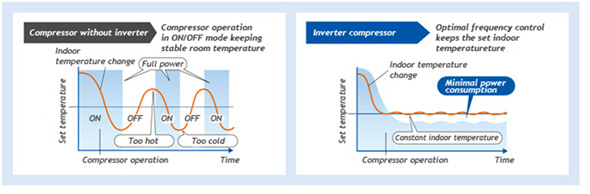

The inverters electronically control the voltage, current and frequency of electrical devises such as compressor motors in heat pump. They receive information from sensors that monitor operating conditions and regulate the speed of the compressors, which directly regulates the power of heat pump. Optimum frequency control reduces excessive electricity consumption and ensures the most comfortable room environment.

Mitsubishi Electric inverters ensure maximum performance and optimum frequency control. The result is optimum power supply for all heating/cooling ranges which leads to maximum comfort (with minimum energy consumption). Quick performance, comfort and low operating costs are the commitments of Mitsubishi Electric.

Economical operation

Low operating costs are a key advantage of inverter devices. Combined advanced inverter technologies with state-of-the-art electronic and mechanical technologies, create synergies that improve heating efficiency. The result is better performance and lower power consumption.

Compressors without frequency converter are started and shut down several times to maintain the set temperature. This repetitive on/off operation consumes excessive amounts of electrical power and affects the service life of unit. Compressors equipped with a frequency converter run continuously – the frequency converter quickly optimizes the operating frequency according to temperature variations. This ensures energy-efficient operation and a more comfortable indoor temperature.

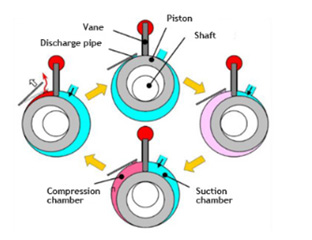

Structure and operating principle

The compressors works by rotating two pistons located on the common shaft. The refrigerant sucked into the compressor is compressed by the rotating piston. The hot, high-pressure gas leaves the compressor and is directed to the heat exchanger. The suction and compression process can be carried out simultaneously in the suction chamber and the compression chamber, which are separated from each other by a vane.

Two compressors in unit PUZ-WZ80VAA

The PUZ-WZ80VAA unit is equipped with two refrigeration systems with two compressors. The main system features an inverter compressor, which by allowing for variable speed, enables adjusting heating capacity to current needs. When the demand for heating power is low, only the inverter compressor operates, enabling smooth power regulation and optimizing energy consumption. The additional system has a fixed-capacity compressor. When the demand increases, the compressor of the additional system is activated. It operates at full heating power, allowing for a rapid response to a decrease in external temperature and, consequently, an increase in the building's heating power demand. This technological solution efficiently manages energy consumption and maintains a stable temperature inside the house.

The unit has improved the structure of the sound insulation of the compressor. The compressor housing cover consists of four layers: rubber/felt/rubber/felt, significantly reducing noise. The external rubber layer has been extended to reduce the open space between insulations. The advanced design significantly lowers the noise level generated by the compressor, ensuring users better acoustic comfort. Additionally, thanks to this innovative construction, the unit performs exceptionally well in applications related to high-density housing, such as townhouses.

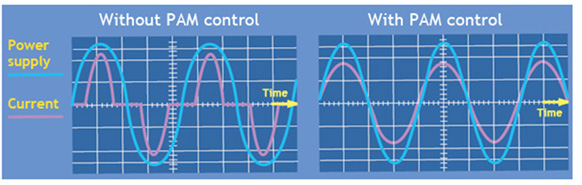

PAM (Pulse amplitude modulation)

PAM is a method of controlling the current, by adapting its path to the voltage. This allows energy to be used more efficiency, with fewer losses. The PAM control allows 98% efficient use of the energy consumed.

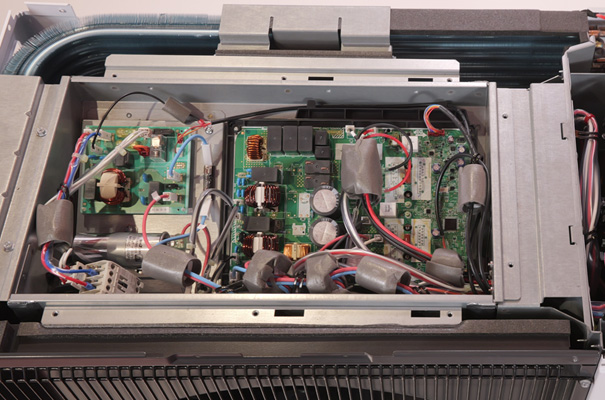

PAM regulates the shape of the current waveform by bringing it closer to the voltage waveform. Extremes are reduced and 98% of the energy is used. - Insulated box with power circuit board

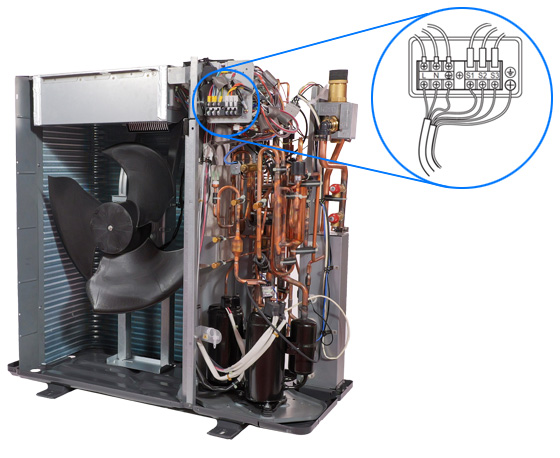

The power circuit board and compressor protection plate are housed in a dedicated, hermetically sealed construction, thereby eliminating the risk of potential ignition from these elements in case of leakage of refrigerant during the operation of the heat pump unit. - Electrical connections

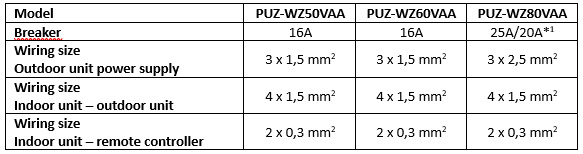

All units of the PUZ-WZ R290 series are single-phase powered. It is necessary to supply them with the following electrical wiring size and to equip the system with an overcurrent protection suitable for the model.

*1 The ability to reduce the protection of PUZ-WZ80VAA to 20A.

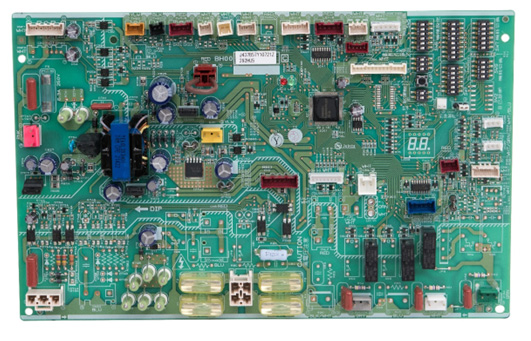

In the PUZ-WZ80VAA unit, breaker size should be 25 A. However, it is possible to limit the device protection to 20 A using DIP SWITCH. As a result of this action, there is also a reduction in heating power at a flow temperature ≥ 45 ˚C.

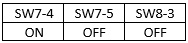

- Stabilizing board

One of the design changes introduced to the PUZ-WZ series units is a double anti-vibration layer. The compressor was placed on a specially designed plate, and vibration isolators were installed under it. The implemented modifications in form of double isolations significantly reduce the noise levels emitted by the compressor.

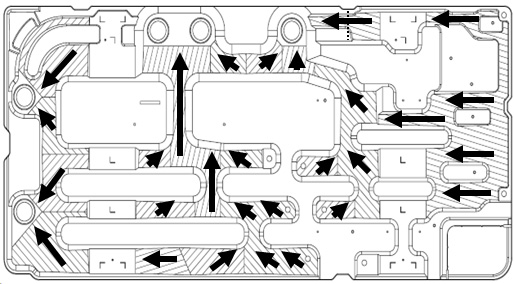

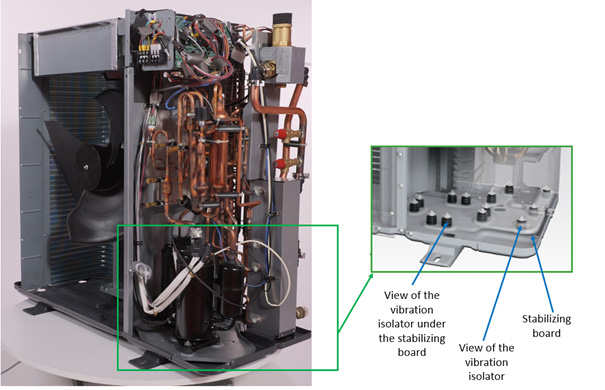

- Inverter board

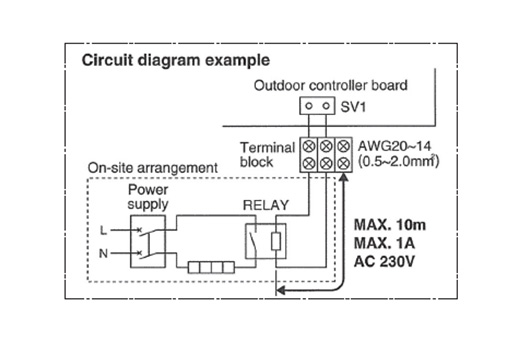

Control board integrated into the outdoor unit of heat pump. It is cooled by a radiator, using outside cold air. In general, the main function of the inverter board is to control the heat pump. However, it has some additional interesting functions worth mentioning. Below you can find a description of several of them:

Drain hose heater connector – MAC-063RA

An optional heater of drain pan or heating cable can be connected to the outdoor unit. This set can be used to activate the heating exhaust to avoid freezing of condensation after the defrost process. The defrost signal is active for 15 min after the defrost process starts.

DIP switch

The outdoor unit has a number of settings defined by the DIP switches on the board, like the indoor unit’s FTC board. Here are a few selected ones:- Auto restart function after power failure - when power is restored, the heat pump continues operation, in the mode it was in before the power failure.

- Defrost setting for higher humidity regions - ability to increase the defrost frequency for a region with higher humidity.

- Pump down function - while moving or disposing of the unit, the refrigerant has to be pumped down from the system according to the pump down procedure.

- Separate power supply for the indoor plate - setting used when the indoor unit is separately powered.

- Manual defrost - forcing defrost in the outdoor unit.