Outdoor unit

Eco Inverter

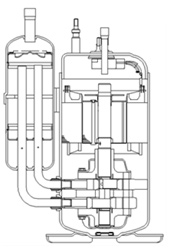

Eco Inverter outdoor unit

- Rotary compressor

For smaller sizes and higher efficiency, Mitsubishi Electric rotary compressors use the original 'Poki-Poki' motor and „Heat Caulking” thermal insulation. They are designed to meet the requirements of the residential and commercial sectors. In addition, the development of an innovative 'Split Centre Plate' manufacturing method has further reduced size/weight and increased performance (energy efficiency).

Automated production line control and customized manufacturing techniques lead to very low defect rates and very high reliability of the product. The quality control process, including robots and experienced personnel, always ensures that each compressor is checked before delivery to the customer. This is the reason why Mitsubishi Electric's quality is known worldwide.

Inverter technology

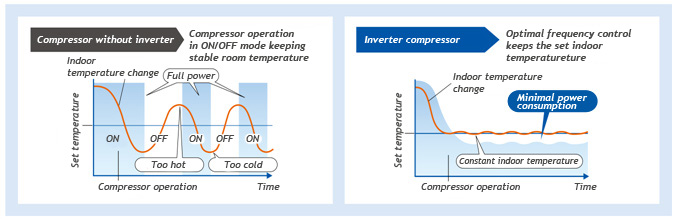

Inverters electronically control the voltage, current and frequency of electrical devices such as the compressor motors in the heat pump. They receive information from sensors that monitor operating conditions and regulate the speed of the compressor, which directly regulates the heat pump output. Optimal control of the operating frequency results in a reduction of excessive electricity consumption and the most comfortable room conditions.

Mitsubishi Electric inverters guarantee the highest efficiency and optimum frequency control. As a result, optimum power is delivered to the units, in all ranges for heating/cooling, and maximum comfort is achieved (with minimal energy consumption). Rapid achievement of set parameters, comfort and low operating costs - these are Mitsubishi Electric's commitments.

Economical operation

Low running costs are a key advantage of inverter units. Combining advanced inverter technology with state-of-the-art electronic and mechanical technologies creates a synergy effect that enables improved heating performance. The result is improved efficiency and lower energy consumption.

Compressors without a frequency converter are repeatedly started up and shut down to maintain the set temperature. This repeated on/off operation consumes excessive amounts of electricity and adversely affects the life of the unit. Compressors equipped with a frequency converter operate continuously - the frequency converter quickly optimises the operating frequency in accordance with temperature changes. This ensures energy-efficient operation.

The number of ON/OFF cycles of the compressor should be a maximum of 10 times/hour. It is therefore particularly important to extend the minimum compressor run time and limit potential uncontrolled heat pump on/off cycles.

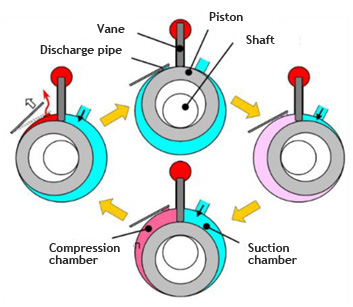

Construction and operating principle

The compressor works by rotating two pistons located on a common shaft. The refrigerant sucked into the compressor is compressed by the rotating piston. The hot, high-pressure gas leaves the compressor and is directed to the heat exchanger. The suction and compression process can be carried out simultaneously in the suction chamber and the compression chamber, which are separated from each other by a vane.

Technology

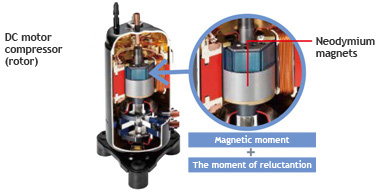

DC reluctance motor

A DC reluctance motor has a rotor fitted with strong neodymium magnets. Reluctance is the resistance of the magnetic system. Thanks to this design, the magnetic torque produced by the neodymium magnets and the reluctance torque, have the effect of increasing the efficiency of operation.

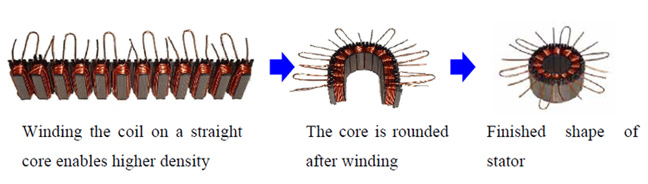

'Joint Lap' type DC motor

Originally designed by Mitsubishi Electric, the unique motor, known in Japan as 'poki-poki', uses 'Joint Lap' technology. The innovative motor has a high power density and high magnetic force, guaranteeing high efficiency and reliability. The special feature of the Poki Poki motor is the motor stator - that is, the assembly of the fixed parts of an electric motor - which does not consist of a single body, but is divided into several parts, called cores. These cores are individually subjected to a coil winding process, which minimises dead space and reduces energy losses, thereby increasing compressor efficiency.

Accumulator on compressor suction The compressor is equipped with an accumulator on the suction pipe. It has several important functions:

The compressor is equipped with an accumulator on the suction pipe. It has several important functions:

• It accumulates liquid preventing it from flowing into the compressor,

•Acts as a silencer, reducing noise levels,

• The internal holes ensure a high reliability of the oil return,

• The suction filter is installed to prevent dirt and other particles from entering the compressor.

Methods for fixing the heat seal The internal components of the compressor have been attached by a thermal sealing method, replacing the existing spot welding method. The risk of deformation of the internal components has been reduced, resulting in higher performance.

The internal components of the compressor have been attached by a thermal sealing method, replacing the existing spot welding method. The risk of deformation of the internal components has been reduced, resulting in higher performance.

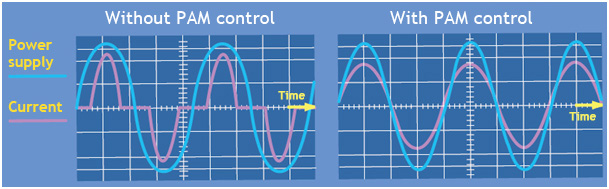

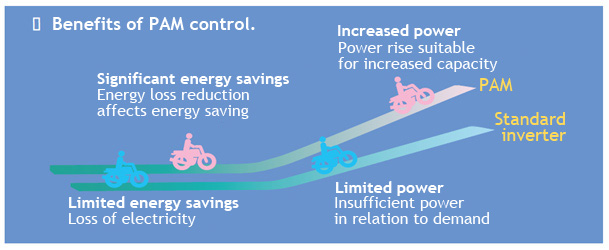

PAM (Pulse amplitude modulation)

THE PAM is a method of controlling the current, by adapting its path to the voltage. This allows energy to be used more efficiently, with fewer losses. The PAM control allows 98% efficient use of the energy consumed.

THE PAM is a method of controlling the current, by adapting its path to the voltage. This allows energy to be used more efficiently, with fewer losses. The PAM control allows 98% efficient use of the energy consumed.

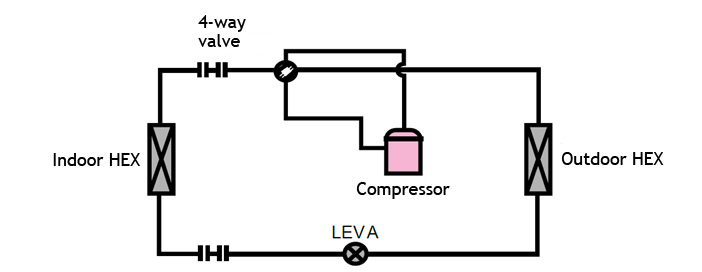

- Refrigerant circuit

LEV electronic expansion valve Expansion valves play an important role in the refrigerant circuit - they determine the ability to adjust the flow rate of refrigerant in the entire system and affect the indoor comfort. Therefore, it is very important to adjust the pressure relief valves precisely. The opening/closing process of the LEV expansion valve is controlled by pulse signals.

Expansion valves play an important role in the refrigerant circuit - they determine the ability to adjust the flow rate of refrigerant in the entire system and affect the indoor comfort. Therefore, it is very important to adjust the pressure relief valves precisely. The opening/closing process of the LEV expansion valve is controlled by pulse signals.

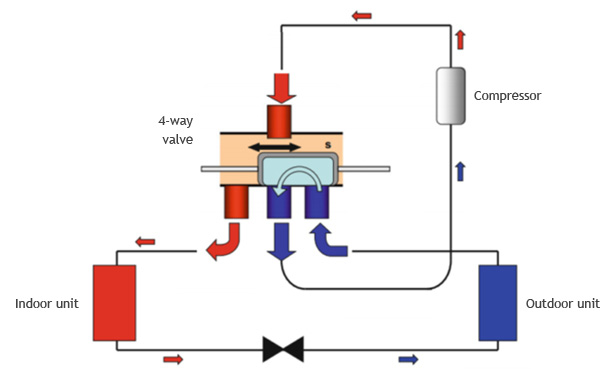

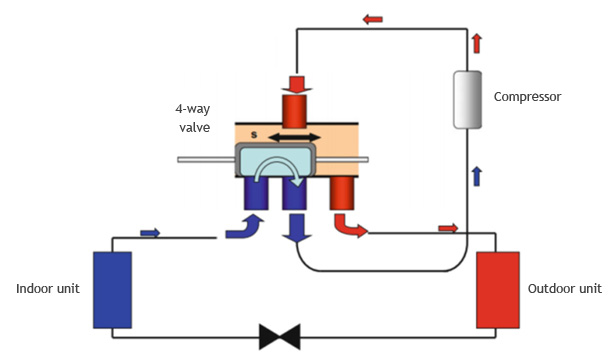

4-way valve

The four-way reverse valve is used to change the direction of the refrigerant flow. In the Eco inverter heat pumps, they are used to switch between heating/cooling and defrost mode.

Heating operation

Cooling operation/Defrost

- Fan

The outdoor unit fan is driven by a high-performance DC motor. This motor provides much higher performance than the corresponding AC motor.

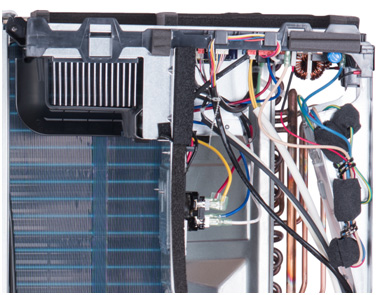

- Inverter board

Control board integrated into outdoor unit. It is cooled by a radiator, using cold outside air. In general, the primary function of the inverter board is to control the heat pump unit. However, it has some additional, interesting features worth mentioning:

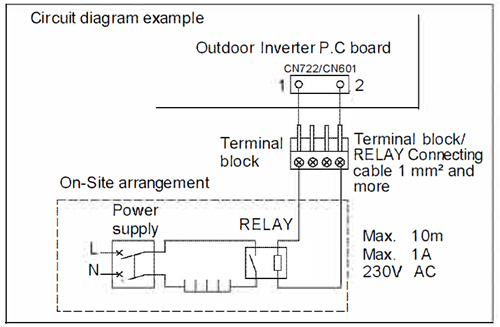

Drain pan heater– Accessory MAC-061RA-E

An optional warming tray heater or heating cable can be connected to the outdoor unit. This set can be used to activate the heating exhaust to avoid freezing of condensation after the defrost process. The defrost signal is active for 15 minutes after the defrosting process begins.

Radiator - electronicscooling

The system electronics are cooled by outdoor air. Air movement occurs due to the underpressure created by the unit's fan. - Temperature sensor

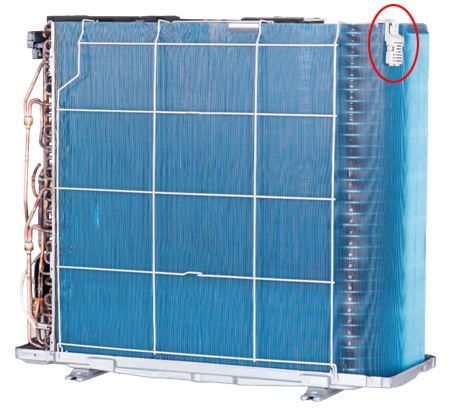

Ambient temperature sensor is a resistance sensor integrated into the outdoor unit. It is placed in a plastic cover to minimize the effect of radiation on the sensor measurement.

- Heat exchanger

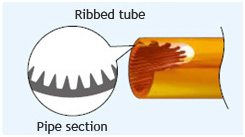

The Eco Inverter heat exchanger is constructed of two copper tubes with aluminum fins. The exchanger is coated with an anti-corrosion coating which is particularly effective in areas with high levels of air pollution. Harmful substances in the air can damage the aluminum radiator lamellas, reducing the efficiency and life of the appliance. The exchangers use improved corrugated copper tubes to increase the heat transfer surface. More heat transfer means more efficiency.

The exchangers use improved corrugated copper tubes to increase the heat transfer surface. More heat transfer means more efficiency.

Performance data

Refrigerant system diagrams